1. Iminyango yenqubo yomnyango newindi

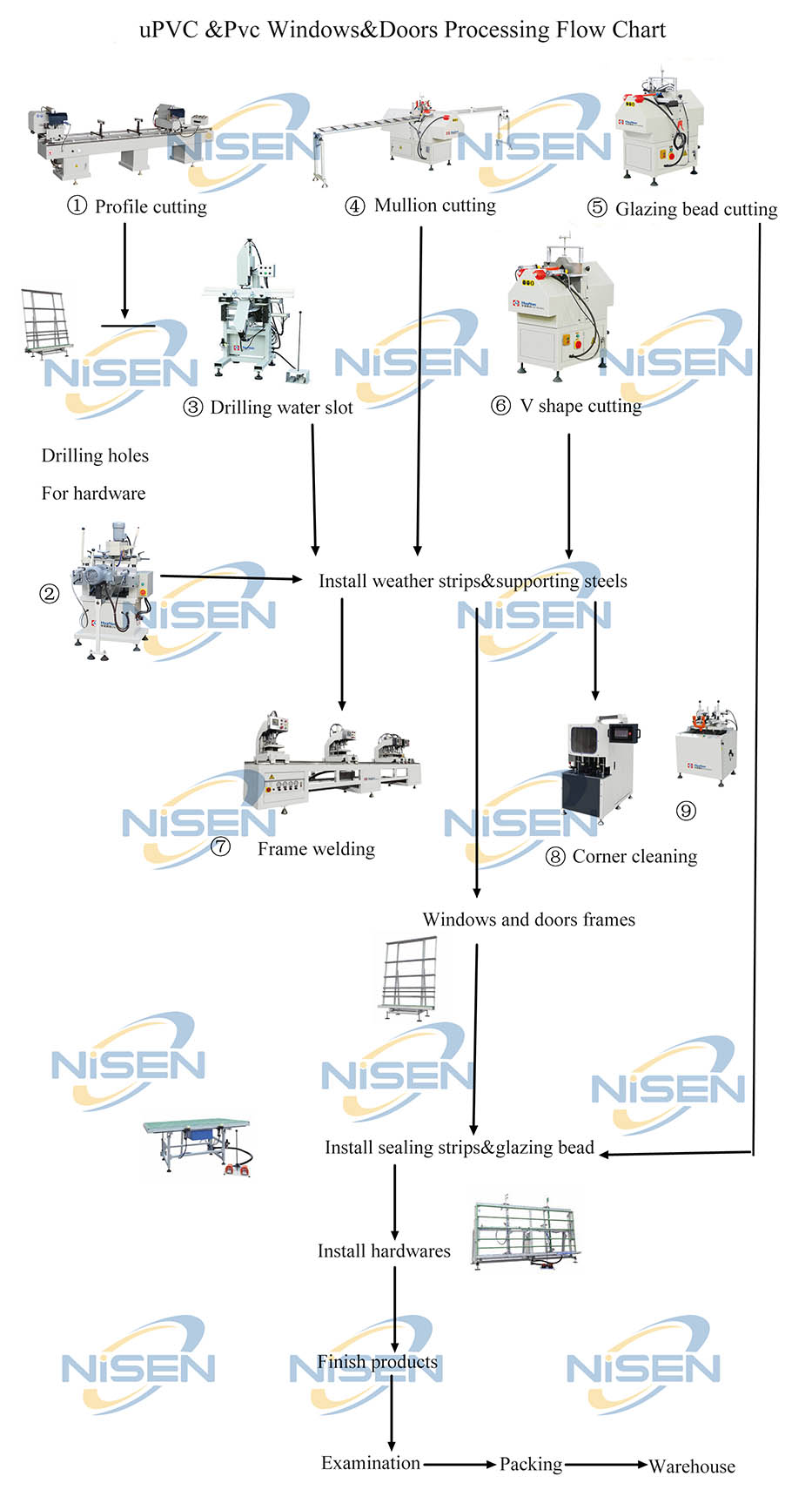

Okokuqala, sicela ubuyekeze ngokucophelela imidwebo yenqubo, unqume uhlobo nobungako bamawindi adingekayo ngokuya ngezidingo zesitayela sokudweba, bese uphetha

Ilungiselelwe futhi ilinganiselwe ubude, futhi yenziwa ngokuya ngohlobo olufanayo nezinhlobo ezahlukahlukene zewindi ukwenza ngcono isilinganiso sokusetshenziswa kanye nezinga lokukhiqiza.

2. Inqubo yokuphepha

Abasebenzi kudingeka bagqoke kahle, bagqoke imikhiqizo yomshuwalense wezabasebenzi ngokwezidingo zomsebenzi, futhi bagxile ekuvikeleni izingozi eziyingozi. I-Pyrotechnics ayivunyelwe ngokuphelele ku-workshop futhi bonke abasebenzi abavunyelwe ukubhema.

3. Iphrofayili yokusika, izimbobo zokugaya amanzi, ama-keyholes

A.Ukufakwa kwephrofayili okuyinhloko ngokuvamile kuvumela ukukhishwa kwamakhandlela amabili. Shiya u-2.5mm ~ 3mm ekugcineni ngakunye kwendaba njengemajini, nangaphansi kokushisela. Ukubekezelelana kwezinto kufanele kulawulwe ngaphakathi kwe-1mm, futhi ukubekezelelana kwe-angle kufanele kulawulwe ngaphakathi kwama-degree angu-0.5.

B.Iphrofayili yohlaka kufanele ifinywe ngemigodi yokuhambisa amanzi, futhi uhlobo lwe-fan kufanele ngokujwayelekile lufakwe izimbobo zamanzi nezimbobo zokulinganisa umoya. Ububanzi bomgodi wokudonsa amanzi bufanele bube ngu-5mm, ubude obungu-30mm, umgodi wokuhambisa amanzi akufanele ubekwe emgodini ngensimbi yensimbi, futhi awukwazi ukungena emgodini ngentambo yensimbi.

C. Uma ufuna ukufaka i-actuator nokhiye womnyango, kufanele ugaye imbobo yokhiye

4. Ukuhlanganiswa kwensimbi eqinisiwe

Lapho ubukhulu besakhiwo somnyango newindi bukhulu noma bulingana nobude obucacisiwe, umgodi wangaphakathi kufanele ube ulwelwesi lwensimbi. Ngaphezu kwalokho, umhlangano wehadiwe Ulwelwesi lwensimbi kumele lufakwe emajoyintini eminyango namawindi ahlanganisiwe kanye nasemalungeni eminyango namafasitela ahlanganisiwe. Futhi ulungise. Insimbi yesigaba engxenyeni ethwala ingcindezi yamajoyinti amise okwe-cross kanye ne-T kufanele kube lapho ipuleti eliphothene lisanda kuphakanyiswa ngemuva kokuba ingxenye incibilikile. Faka insimbi yesinqe ekuqaleni bese uyilungisa ngemuva kokushisela.

Izinto zokubopha ulwelwesi lwensimbi ngeke zibe ngaphansi kuka-3, isikhala ngeke sibe sikhulu kuno-300mm, futhi ibanga ukusuka ekugcineni kwensimbi yesigaba ngeke libe likhulu kune-100mm. Akufanele kube nezimbobo ezingezansi ezingaphansi kwezingu-3 (izingcezu zokulungisa) zefasitela lonke, isikhala asifanele sibe ngaphezu kuka-500mm, futhi ibanga ukusuka ekugcineni kwewindi akufanele libe likhulu kakhulu. Ku-150mm. Ukuxhumeka okwenziwe ngo-T kudinga ukuba nezimbobo ezihlanganayo ngo-150mm ezinhlangothini zombili zokuxhaswa okuphakathi

5. Ukushisela

Lapho ushisela, naka ukushisa kokushisela okungu-240-250 ° C, ingcindezi yokuphakelayo engu-0.3-0.35MPA, ingcindezi yokubambelela engu-0.4-0.6MPA, isikhathi esincibilika imizuzwana engama-20-30, isikhathi sokupholisa amasekhondi angu-25-30. Ukubekezelelana kwe-Welding kufanele kulawulwe ngaphakathi kwe-2mm Ngaphakathi

6. Sula amakhona, faka amapheshana enjoloba

A. Ukuhlanzwa kwe-engeli kwehlukaniswe ukuhlanza ngesandla nokuhlanza ngemishini. Ngemuva kokushisela, i-engeli ingahlanzwa ngemuva kwemizuzu engu-30 yokupholisa.

B. Uzimele, isilawuli sefeni nengilazi yobuhlalu, faka izinhlobo ezihlukene zezingcezu zenjoloba ngokwezidingo. Uzimele, ingxenye yomugqa wenjoloba yomlandeli;

Ubude bomucu wenjoloba kufanele bube cishe u-1% ubude ukuvimbela umucu wenjoloba ekunciphiseni. Akukho okuxegisayo, okwehlisayo, noma okumaphakathi ngemuva kokufakwa kwaphezulu kwenjoloba

I-Docking phenomenon

7. Umhlangano wehadiwe

Iminyango nama-windows aqediwe epulasitiki-insimbi ahlanganisiwe kusuka kuhlaka nefeni nge-hardware. Umgomo womhlangano wehadiwe uwukuthi: Amandla anele, indawo elungile, ukuhlangabezana nemisebenzi eyahlukahlukene nokulula ukuyishintsha, i-hardware kufanele ilungiswe kuhlobo olufakiwe olwenziwe kahle Ensimbeni yolwelwesi, izikulufo ze-Hardware fixing kufanele zifakwe ngokuphelele, nendawo yokufaka Okwezingxenyekazi zekhompiyutha kufanele kuhambisane nezinga elijwayelekile.

8. Ukufakwa kwengilazi

Engxenyeni lapho kuzofakwa khona ingilazi, beka kuqala ingilazi, ubeke ingilazi esikiwe ebhlokweni, bese udlulisa ingilazi Ubuhlalu bengilazi bubamba ingilazi ngokuqinile.

9.Ukuqedwa komkhiqizo nokuhlolwa kwekhwalithi

Ngaphambi kokuba kwenziwe iminyango namawindi futhi bashiye ifektri, badinga ukuhlanganiswa ukuze kuvinjelwe ukungcola. Ngaphansi kwesisekelo sokufakwa komsindo, ukupakisha okukodwa. Iteyipu yokufaka emaceleni eyodwa ngeke ibe ngaphansi kwamaphoyinti ama-3 futhi isikhala asisoze saba ngaphezu kwama-600 mm. Ngemuva kokupakisha, maka usayizi wewindi endaweni evelele. Ngemuva kokuthi kuhlanganiswe iminyango yepulasitiki namawindi, kudingeka ukuhlolwa okuqinile kwekhwalithi.

A.Ukuhlola ukubukeka: Ubuso beminyango namawindi kufanele bushelelezi, bungabi namabhamuza nemifantu, kufane ngombala, futhi ama-welds kufanele abushelelezi, futhi kungabikho zibazi ezisobala. Amaphutha afana nokungcola;

B. Ukuhlola usayizi wokubukeka: lawula ngokuqinile ikhwalithi yeminyango namawindi ngaphakathi kokuchezuka okuvumelekile kwezinga lomkhakha kazwelonke;

C. Imichilo yokufaka uphawu ifakwe okokufana ngeziqongqo, amalunga aqinile, futhi akukho mkhuba we-grooving;

D.Umucu wokufaka uphawu kufanele uhlanganiswe ngokuqinile, futhi igebe eliphakathi kwamakhona namalunga wezinqa akufanele libe likhulu kuno-1mm, futhi akufanele abe sohlangothini olufanayo. Sebenzisa imichilo yokunamathisela emibili noma ngaphezulu;

E. Izesekeli zehadiwe zifakwe endaweni efanele, zigcwaliswe ngobuningi, futhi zafakwa ngokuqinile.

Isikhathi Iposi: Aug-23-2021